You are here

General information about germicidal lamps PROLUX G®

Germicidal lamps PROLUX G ®

Germicidal lamps PROLUX G ® under direct and indirect radiation

Ultraviolet radiation

Ultraviolet radiation can be described as an optical, electromagnetic, radiation with a wavelength of 100 nm to 1 mm.

Ultraviolet radiation with a wavelength of 100 nm to 400 nm can be divided into:

UVA 315-400 nm

UVB 280-315 nm

UVC 100-280 nm

Germicidal radiation

Germicidal radiation - UVC wavelength 253.7 nm is invisible. This radiation, in the UVC spectrum, causes decay of microorganisms by disrupting their DNA and thus destructing them. The blue light produced by germicidal lamps is only a side product in this case and it is not disinfecting. Germicidal radiation does not permeate through dim, non-transparent materials, or regular glass. This radiation only permeates through a clear quartz glass and special Teflon foil.

Germicidal lamps

Germicidal lamps are devices that serve for disinfection by using of ultraviolet radiation with a wavelength of 253.7 nm. Germicidal lamps PROLUX G ® are class II. Medical instruments and thus are checked and tested by a certified person, by numerous clinical tests, they are registered and approved by SUKL (The State Institute for Drug Control). Their usage and effectiveness have been tested over decades of practical experience. If used properly, no harm can be caused by unwanted exposure. It is however necessary to adhere to some principals.

- When constructing and positioning the device it is inevitable to ensure that the personnel or the patients are not directly exposed to the UVC radiation. Due to the fact that this radiation can effectively destroy germs in a large spectrum, it creates a healthy environment and thus protects individuals from various diseases and possible infections.

This concerns an additional, however when used well, very effective disinfection. The radiation is homogenic and therefore destroys germs also at places where no disinfectant were applied (outside of the area where obstacles have created a shade). The radiation that passes through the room can also destroy germs that are found on dust particles within the air and thus it also disinfects the actual air. The sources of radiation, in this case germicidal lamps PHILIPS TUV 30W LL, or an equivalent OSRAM HNS OFR 30W LL have a guaranteed lifetime corresponding to 8000 hours when the intensity of UVC radiation is lowered to 80% of the initial value. After this period, it is necessary to replace them. The lifetime of these lamps might also be affected by the number of times they have been turned on and off and whether electronic ballasts with a ‘soft start’ have been used. In the case of PROLUX G®, all the above mentioned conditions are fulfilled.

- Only individuals who have been informed about the usage and the potential risks associated with using germicidal lamps can operate with them and this information must be noted down in a written form. In addition, using germicidal lamps in the presence of people is only possible in monitored areas, where the personnel have been taught and informed accordingly and where the safety is secured by using supplementary devices. These are for instance places with a regular regime, where there is a low chance for accidental, unpredictable situations to occur. As to the installation process, only competent individuals who are trained and knowledgeable about the subject and are in possession of an appropriate permission based on a project developed by an authorised individual are allowed to install germicidal lamps. In order to put the device into service, it is necessary to apply the operating rules that are designed for each individual workplace, are in accordance with the legislation and approved by a competent public health authority.

- It is necessary to complete an annual check of performance of the germicidal lamps as well as to secure a control of switches and other additional technical devices, in case they have been used.

- Marking the lamps with warning labels against UVC radiation. The entrance doors in each department of a hospital need to have a visible warning label informing about the presence of UVC radiation. To enhance the security when using the directly radiating lamps it is possible to use a motion sensor. If the sensor detects a movement of persons in the area where the UVC radiation is present, it will automatically turn off the device for a time period that has been pre-determined. Once this time period is over, the sensor will automatically turn on. In order to completely avoid the possibility of interfering with the unwanted radiation, it is possible to use a door sensor. When the door opens, the sensor will immediately ensure that the lamp turns off and it will only turn back on once the door is closed. In order to ensure complete protection against radiation in the exposed area it is necessary to employ both of the aforementioned methods. A situation can occur where the hospital personnel close the door from the inside and thus the lamps gets turned on again. It is crucial to follow the respective rules and regulations especially at places where many individuals interact every day, given that despite proper training of the personnel errors can occur as a result of doing routine work. Places where these procedures are necessary to follow are such where high cleanliness needs to be ensured even if the technical devices that ensure safety against UVC radiation require higher investments.

Exposure to UVC radiation doses without adverse side effects

Due to the use of sources with a hot cathode (to 0.5 m from the source there is relatively high performance of UVC radiation) long exposure times are not necessary for the destruction of microorganisms. The intensive air flow across the active zone of UVC radiation leads to effective disinfection of air and surface in the irradiated space. As illustrated in the table below, the deactivation process might take only a few seconds. However, it is necessary to ensure multiple exposure to radiation within 24 hours. Programmable switch timer SPH 01, 02 allows for a repeated turn-on in four pre-set times. The effectiveness of UVC radiation decreases by the square of distance. When using directly radiating germicidal lamps, it needs to be envisaged that at a certain temperature and humidity, disinfection can be less effective as distance from the germicidal lamp increases. Noticeable decline occurs at about three meters from the source of UVC radiation.

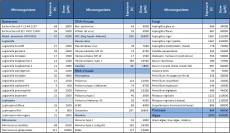

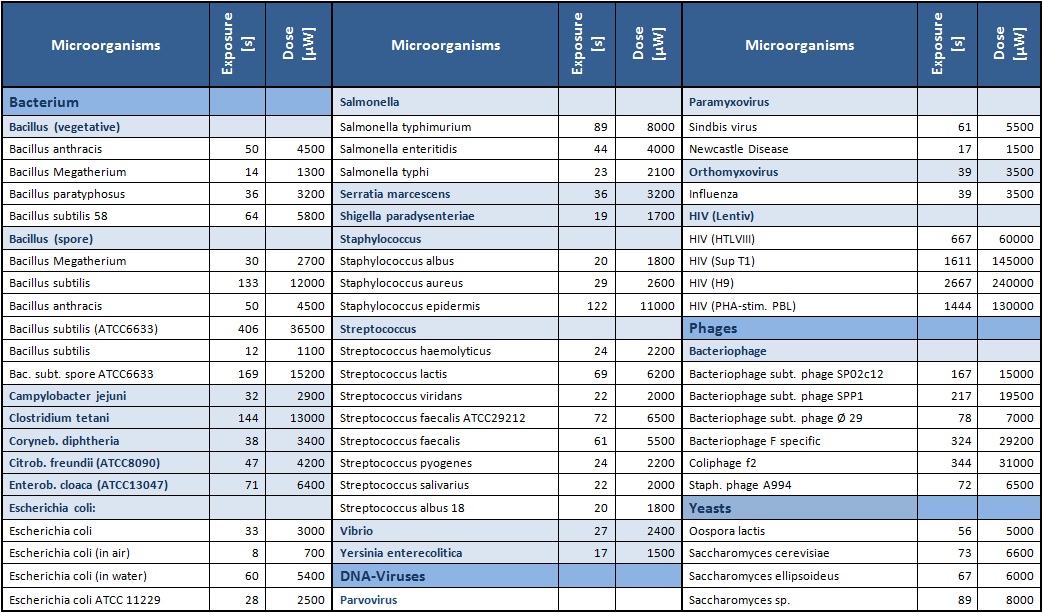

Table: The radiation dose required for 90% inactivation of microorganisms from a distance of 1m from the UVC source. Dose in μW/sek/cm2

(The exposure values apply when using the following sources of UVC radiation: intensity 90 µW - OSRAM HNS 30W OFR and PHILIPS TUV 30W LL)

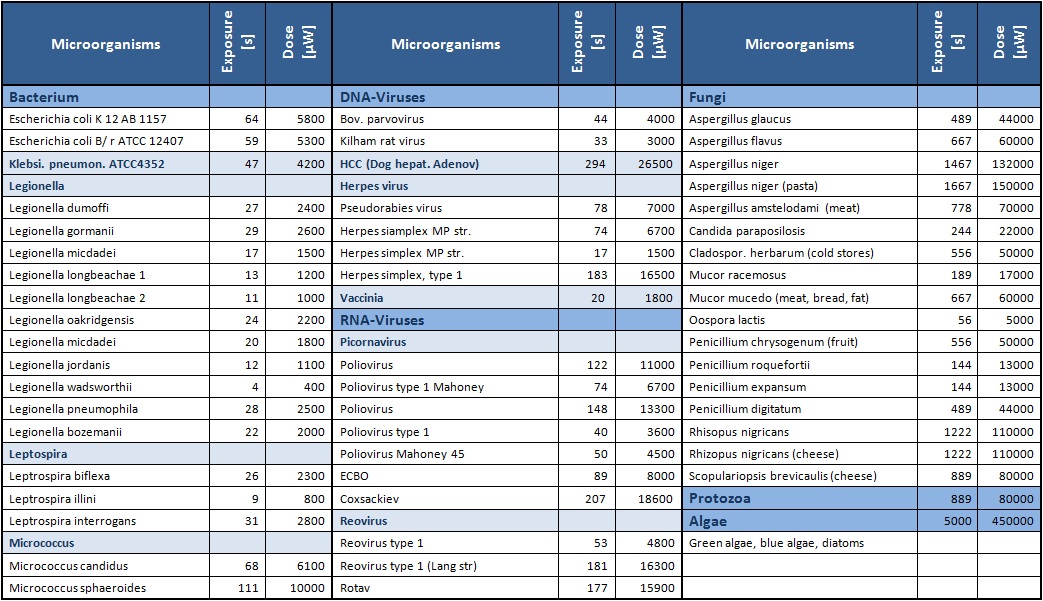

Exposure limit values for non-coherent optical radiation

Using of proper exposure time and ensuring its correct repetition in a specified time interval. Directly and indirectly radiating germicidal lamps

Lamps with a hot cathode are used as sources of UVC radiation. When a 30W source is used, 90 microwatts per second are produced from the distance of 1 meter for the surface 1cm2. Exposure times for this distance are short and the disinfection in the active zone is very effective. It is therefore important that the operation is carried out repeatedly and at short intervals. This way, a large volume of air is in the room is effectively disinfected (without the use of air conditioning every six hours there is a complete replacement, or relocation of air in the monitored area).

Lamps with a hot cathode are used as sources of UVC radiation. When a 30W source is used, 90 microwatts per second are produced from the distance of 1 meter for the surface 1cm2. Exposure times for this distance are short and the disinfection in the active zone is very effective. It is therefore important that the operation is carried out repeatedly and at short intervals. This way, a large volume of air is in the room is effectively disinfected (without the use of air conditioning every six hours there is a complete replacement, or relocation of air in the monitored area).

a., the above-mentioned information applies only when directly radiating lamps are used - without the presence of people. When operating, it is necessary to ensure strict adherence to safety rules and recommendations.

b., when using indirectly radiating lamps (sanitized air passes through the enclosed space of the lamp in a very small distance from the UVC sources). This leads to very effective disinfection of air passing through; however its volume is limited by the power of the ventilators used. This volume is determined by the size of the actual germicidal lamp as well as by the fact that when a larger volume of air is being filtered, an increase in acoustic noise occurs.

When operating, it is not necessary to ensure strict adherence to safety rules and recommendations, as when used properly, there is no possibility to get in contact with the dangerous UVC radiation. The level of this radiation is zero at both the input and output grid. It is recommended that in order to ensure proper disinfection by the lamps it is necessary to extend their operating time as much as possible. This applies for such situations where contamination might occur, created by the people currently present in the room, or in order to ensure the highest level of disinfection possible, these lamps can be used in a continuous mode. To achieve an economic operation, it is recommended that programmable switch timer SPH01, or SPH01A is used, which is part of the lamp.

Keeping a regular and accurate UV exposure in the active zone

In order to achieve proper function of disinfection by using UVC radiation it is necessary to ensure regular and accurate UVC exposition times. It is absolutely necessary to exclude the human factor as a source of potential errors and inaccuracies. For such an operation it is necessary to use a programmable switch timer with operating hours counter (eg. SPH 01), as the durability of the UVC sources is limited. However, the operation of such a switch timer should also be checked four times a year. It is also necessary to check the number of operating hours to see whether they correspond with the programmed exposure values. Only then it can be ensured that there will be no increased and unwanted exposure. It is essential to keep written documentation about all these facts, so that any potential problems can be traced and eliminated.

The risk of exposure to artificial optical radiation

When using germicidal lamps, a situation may occur where persons are exposed to artificial optical radiation. This can occur as a result of:

- Incorrect use of exposition time and incorrect positioning of the germicidal lamp in a room (it is important to follow the recommended exposure times in order to comply with the limit values of exposure to optical radiation on the one hand and to achieve effective disinfection on the other hand). It is essential to place the lamps at the correct place in a room and ensure that the direction of UVC rays is such that it does not create unwanted exposure to UVC radiation.

- Incorrect handling of germicidal lamps by the personnel (personnel must be thoroughly trained and instructed on the principle of disinfection by UVC radiation as well as possible risks that occur as a result of unauthorized and incorrect handling of the UVC sources).

- Unforeseen disturbances (personnel must be trained and instructed to be able to cope with and solve unforeseen events and disturbances such as i.e. release of the mounted lamp – change in the radiation diagram, inability to turn the device off, incorrect positioning in a room, breakage of tube - source of UVC, mercury contamination of the surrounding area as a result of breakage.

Measures to follow in case of intervention with artificial optical radiation (accidents, or other unforeseen circumstances)

When using germicidal lamps type GK there shall in no case be an interaction of people with UVC radiation and thus such situation where people are exposed to radiation produced by UVC sources can be excluded. In other words, the intervention of the unprotected human body with UVC radiation can be absolutely excluded. Despite compliance with all safety measures when using these lamps, a situation may arise in some emergencies and unforeseen circumstances where one is exposed to a small dose of unwanted UVC radiation that does not exceed the maximum value allowed; 30 J.m2.

Given the nature of UV radiation (no visible characteristics - color, odor, thermal effect) there are no accompanying phenomena at the moment when one has been exposed to it. These appear after a certain period of time - several hours, depending on the size of the exposure. Lighter symptoms of being exposed to UVC radiation are strong burning in the eyes, or redness of skin. In the case of larger or long-term exposures - eye damage, skin burns, or skin cancer. Even when one has a suspicion of having been exposed to UVC radiation, or has any of the aforementioned symptoms, it is necessary to seek medical help. The provider needs to ensure immediate removal of the cause, analyze the cause of the problem, take effective preventive measures and continue to monitor safety at places where germicidal lamps are installed.

Other potential risks

Tubes - sources of UVC radiation - are essentially liner lamps that contain mercury vapors without the inner layer of phosphor. If these lamps break the surrounding area gets contaminated by mercury, which is a toxic substance for human body. Additionally, one can also get injured by the glass splinters of the broken lamp. When handling the lamps it is necessary to ensure that under no circumstances they break, or get damaged. When the lamps are damaged or their period of service has expired they need to be liquidated in accordance with the toxic waste disposal system either by the manufacturer or by companies authorized for disposal of such waste. In order to prevent leakage of mercury vapors into the surrounding environment and to protect against glass splinters it is recommended to use tubes with protective Teflon coating, which serves as a packaging for the broken tube and thus prevents the leakage of mercury vapors and glass splinters into the environment.

Final provision

The manufacturer declares that if one complies with the aforementioned rules and regulations, the use of the devices is highly effective and safe. These facts have been verified by various measurements, by the data provided by manufacturers of UVC sources, by using technical information on similar products of world renowned manufacturers as well as by the manufacturer’s years of experience. The manufacturer reserves any changes and adjustments in the materials by another person without authorization.

The information listed above is the intellectual property of the company Nexa, s.r.o. All rights reserved under copyright law. Publication, copying and further distribution of this information is allowed only with consent of the author.